Filament Types

FDM filaments can be classified into several primary categories: general purpose, specialty, engineering grade, high performance, ultra-high performance, and support.

*high performance, ultra-high performance, and support categories are not listed below

Polylactic Acid (PLA)

The most trouble-free material to print with. Comes in a wide range of available colours.

Has a wide variety of styles - silk, matte, marble, luminous, rainbow, galaxy, chameleon, wood, and metal, just to name a few.

Great for prototypes, cosplay, or any indoor display pieces where tensile strength chemical and UV resistance are not required.

Typically made from corn grain and is non-toxic.

Note: Will warp if exposed to high ambient temperatures for sustained periods.

Category: general purpose

Material Cost: $

Polyethylene Terephthalate Glycol (PETG)

Slightly more robust than PLA, with higher temperature resistance, great flexibility, higher resistance to impact, great chemical resistance, waterproof, and also food-safe. Perfect for prints that will come in contact with food.

Comes in a large range of colours.

Note: Can be used outdoors but direct UV will slowly deteriorate it over a few years.

Category: general purpose

Material cost: $$

Acrylonitrile Butadiene Styrene (ABS)

The most common plastic used in the automotive industry due to its strong durability, flexibility, UV and chemical resistance.

Has a moderate range of available colours.

Can be smoothed to a gloss finish with acetone vapor smoothing (this will further increase the bond between layers but may lose some finer details).

Note: More prone to slight dimensional changes (up to 0.25mm) or warping during the cooling process.

Category: general purpose

Material cost: $$

Acrylonitrile Styrene Acrylate (ASA)

When durability, tensile strength, heat, UV, and chemical resistance are paramount, this is the go-to material of choice. Fantastic for automotive or outdoor applications.

Limited colour range; typically black, natural or grey (some brands like Polymaker offer a few more colours).

Fantastic for functional end-use parts.

Can be smoothed to a gloss finish with acetone vapor smoothing (this will further increase the bond between layers but may lose finer details).

Note: More prone to slight dimensional changes (up to 0.25mm) during the cooling process.

Category: general purpose

Material cost: $$$

Polycarbonate (PC)

Greater impact and heat resistance when compared to ASA/ABS. Fantastic for functional end-use parts that will be exposed to consistently higher temperatures.

Very limited colour range; typically only comes in black, natural or transparent.

Note: once damaged/deformed it will not reform to its original shape.

Category: engineering grade

Material cost: $$$

Polyamide (PA12)

Engineering grade material. This is one of the top picks when you require a super tough and robust material. Nylon (PA12) is a self-lubricating plastic with low moisture absorption, low shrinkage during printing, and an amazingly high thermal deformation temperature threshold. Extremely resistant to abrasion wear and tear. Top choice for machinery parts or parts that will be under continual stress. ie. mechanical gears

Limited colour choices; typically black, white or natural.

Category: engineering grade

Material cost: $$$$

Carbon Fibre (CF)

Most FDM material types have available carbon fibre options, such as PLA, PETG, ABS and PA12.

Carbon fibre shreds have been added to these filaments to increase rigidity, toughness, flame resistance and tensile strength.

Note: typically the percentage ratio of carbon fibre to plastic is 15% carbon fibre or greater.

Category: n/a

Material cost: $$$$

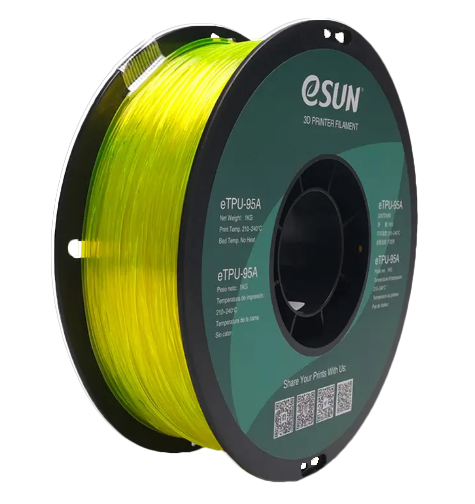

Thermoplastic Polyurethane (TPU)

Strong resistance to impacts, tears and cuts.

Very flexible material with some rigidity. Typically will reform back to its original shape due to its elasticity.

Limited colour options.

Typical applications: phone cases, RC tyres, or other rubberised items that require some level of rigidity.

Category: specialty

Material cost: $$

Thermoplastic Elastomer (TPE)

Strong resistance to impacts, tears, and cuts.

Highly flexible material. Reforms back to its original shape due to its elasticity.

Soft to the touch

Very limited colour options.

Typical applications: o-rings, seals, or anti-vibration devices due to their excellent dampening properties.

Category: specialty

Material cost: $$

Contact Us Today!

Explore a limitless realm of possibilities with our 3D printed creations. Stay connected with us on social media to witness our innovative projects and designs.

Business Hours

- Mon - Fri

- -

- Sat - Sun

- Closed

Contact Us

Thank you for contacting us. We will get back to you as soon as possible.